The Tech Renaissance: How Innovations are Reshaping Manufacturing

In the present high-speed world, mechanical advancements are altering each industry, and the assembling business is no exception. From mechanization to information investigation, different tech progressions are reshaping the way that merchandise is delivered, upgrading productivity, quality, and supportability. We should dive into a few key regions where innovation is driving critical advancement in manufacturing.

Contents

- Automation and Robotics: Enhancing Efficiency and Precision

- Internet of Things (IoT) and Connectivity: Optimizing Operations

- Vibration and Condition Monitoring: Ensuring Equipment Reliability

- Data Analytics and Artificial Intelligence: Driving Insights and Innovation

- Additive Manufacturing: Redefining Production Paradigms

Automation and Robotics: Enhancing Efficiency and Precision

Perhaps one of the main progressions in production is the broad reception of robotization and advanced mechanics. Processes are streamlined, errors are reduced, and productivity is improved by these technologies. Advanced sensors and artificial intelligence (AI) algorithms enable robots to carry out intricate tasks with the utmost precision, resulting in increased output rates and decreased production costs. In addition, manufacturing environments are increasingly incorporating collaborative robots, or cobots, that collaborate with human operators to improve safety and efficiency.

Internet of Things (IoT) and Connectivity: Optimizing Operations

The Internet of Things (IoT) has arisen as a distinct advantage in the assembling sector, empowering consistent networks and ongoing information trade across machines, gadgets, and frameworks. By implanting sensors and actuators into hardware and creation lines, producers can screen execution, track stock levels, and prudently distinguish support issues. This network works with prescient support, limiting personal time and forestalling expensive breakdowns. Also, the IoT-empowered inventory network management improves permeability and spryness, empowering producers to answer quickly to market changes and client requests.

Vibration and Condition Monitoring: Ensuring Equipment Reliability

In manufacturing environments, hardware dependability is central to keeping up with smooth activities and limiting disturbances. Technologies for vibration and condition monitoring are essential for ensuring the health and performance of machinery. By sending sensors to quantify vibration levels and different marks of gear condition, producers can identify early indications of wear, misalignment, or looming disappointments. This proactive way to deal with support takes into consideration ideal mediation, forestalling exorbitant breakdowns and drawing out the life expectancy of resources. For the best wireless monitoring services, manufacturers are turning to cutting-edge solutions that offer real-time insights and predictive capabilities.

Data Analytics and Artificial Intelligence: Driving Insights and Innovation

Data analytics and artificial intelligence (AI) are enabling makers to extricate noteworthy bits of knowledge from tremendous measures of information created all through the production interaction. By utilizing progressed calculations and AI methods, makers can improve asset use, gauge requests all the more precisely, and upgrade item quality. AI-fueled prescient investigation empowers proactive direction, from booking creation rushes to enhancing energy utilization. In addition, artificial intelligence calculations can distinguish examples and irregularities of production information, empowering constant cycle improvement and successful business practices.

Additive Manufacturing: Redefining Production Paradigms

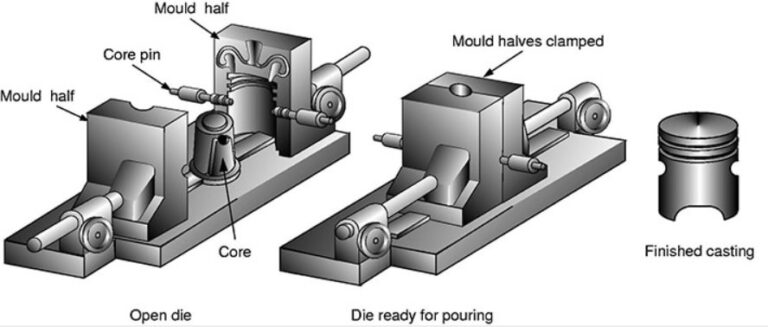

By enabling the creation of intricate geometries with unprecedented speed and efficiency, additive manufacturing, more commonly referred to as 3D printing, is reshaping conventional production processes. This innovation fabricates objects layer by layer from computerized plans, disposing of the requirement for molds or tooling. On-demand production, rapid prototyping, and flexibility in design iterations are all provided by additive manufacturing, which significantly shortens the time it takes for new products to go to market. Enterprises going from aviation to medical services are embracing 3D printing for its capacity to deliver lightweight yet durable components and customized medical implants.

In conclusion, innovation keeps on driving surprising headways in the assembling sector, from computerization and advanced mechanics to IoT availability, information examination, and added substance production. These advancements are upgrading functional proficiency and item quality as well as cultivating more noteworthy deftness and supportability across the manufacturing value chain. Embracing these mechanical progressions empowers makers to remain serious in an always developing worldwide commercial center, meeting client assumptions while driving nonstop improvement and advancement. As the industry evolves, leveraging the latest technologies will be key to unlocking new opportunities and achieving sustainable growth.