Sheet Metal Fabrication in Electronics Industry: Benefits and Applications

welder welding a metal sheet

Meta Description: Sheet metal fabrication entails transforming flat metal sheets into metal structures. This article delves into the unique advantages and applications of this versatile manufacturing process in the electronics industry.

Sheet metal fabrications remains a crucial process in electronics manufacturing. It serves as the mainstay for shaping precise and customized components that form the groundwork of devices like TVs, monitors, and projectors. Continue reading this article to discover how sheet metal fabrication contributes to both the advancement and application of electronic technology.

Contents

Benefits of Sheet Metal Fabrication in the Electronics Industry

rolled sheet metal tile in an industrial plant

Sheet metal fabricating offers numerous advantages that are essential to the electronics industry. Owing to its versatility and precision, sheet metal fabrication empowers manufacturers to meet the ever-changing demands of the market while delivering high-quality solutions tailored to specific needs.

Below are some of the diverse benefits of sheet metal fabrication in electronic manufacturing:

- Customization

One of the key reasons sheet metal fabrication remains highly valued in the electronics industry is that it allows for customization. With this process, manufacturers can tailor solutions to meet specific design needs.

By leveraging advanced Computer-Aided Design (CAD) software and Computerized Numerical Control (CNC) machining capabilities, precise engineering of sheet metal components becomes possible. Hence, this enables the manufacture of custom-made components that align perfectly with the intended application.

- Precision

Precision is a hallmark of sheet metal fabrication, ensuring accuracy in manufacturing electronic components. Through meticulous planning and execution, manufacturers achieve consistency in the dimensions and specifications of sheet metal parts. This precision remains crucial in maintaining the functionality and integrity of electronic devices, minimizing errors, and enhancing performance.

- Versatility

The versatility of sheet metal fabrication allows manufacturers to adapt to diverse requirements and consumer preferences within the electronics industry. Sheet metal fabrication satisfies various roles in the electronic industry. This may include shaping intricate enclosures, crafting mounting brackets, or forming heat sinks. Furthermore, its ability to accommodate multiple materials, thicknesses, and finishes further enhances its versatility. This makes the sheet fabrication process a preferred choice for a wide range of electronic applications.

- Efficiency

Efficiency is a key benefit of sheet metal fabrication, streamlining production processes in the electronics industry. The use of advanced machinery and automation reduces lead times and enhances productivity. Additionally, the ability to produce complex shapes and features in a single operation minimizes the need for secondary processing, saving both time and resources.

- Fast Production

Agility is essential in today’s fast-paced electronics industry, and sheet metal fabrication offers the flexibility needed to respond quickly to market demands. Manufacturers can adjust production schedules, modify designs, and accommodate last-minute changes with relative ease. This agility enables companies to stay competitive in a rapidly evolving market, delivering quality components on time and meeting customer expectations.

Applications of Sheet Metal Fabrication Components

an engineer in a TV factory

Sheet metal fabrication components find diverse applications across various electronic devices, such as TVs, monitors, and projectors. Overall, they help enhance their functionality and aesthetics.

Let’s delve into the specific applications within the electronics industry:

- TV

Sheet metal fabrication is vital to the construction of televisions as it contributes to their structural integrity and aesthetic appeal. Sheet metal components such as chassis, back panels, and stand mounts are commonly used.

The chassis provides the framework for housing the internal components of the TV, ensuring proper alignment and protection. Back panels, typically made of sheet metal, offer support for mounting hardware and facilitate connectivity with external devices. Additionally, stand mounts crafted from sheet metal provide stability and adjustability, allowing users to position their TVs for optimal viewing experiences.

- Monitors

Monitors rely on sheet metal fabrication components to provide support structures and sleek designs. Manufacturers use sheet metal for parts such as monitor stands, bezels, and back casings.

Monitor stands produced from sheet metal provide stability and flexibility. This allows users to adjust the height and angle of their monitors for ergonomic comfort. Bezels are frames surrounding the monitor screen, often precision-crafted from sheet metal to enhance the monitor’s visual appeal. Back casings made of sheet metal protect the internal electronics of the monitor while also contributing to its overall durability.

- Projectors

Sheet metal fabrication components also play a vital role in the construction of projectors, providing durability and heat management capabilities. Projector makers often use sheet metal components such as outer casings, heat sinks, and mounting brackets.

Outer casings manufactured from sheet metal offer protection for the delicate internal components of the projector. These casings also contribute to their sleek appearance. Heat sinks made of sheet metal help dissipate heat generated by the projector’s lamp and electronics, ensuring optimal performance and longevity. Additionally, mounting brackets crafted from sheet metal provide secure installation options for mounting projectors on various surfaces.

- Electronic Players

Electronic players, such as Blu-ray or DVD players, employ sheet metal fabrication components to enhance both their functionality and aesthetic appeal. Generally, sheet metal components such as enclosures, front panels, and disc trays come into play when producing electronic players.

Enclosures from sheet metal fabricators provide protection and support for the player’s internal electronics. This further helps ensure reliable performance and longevity. Front panels made of sheet metal provide user interface options such as buttons and displays. Disc trays produced from sheet metal offer secure storage and retrieval options for discs. Thus, this ensures smooth operation and minimal wear over time.

Various Fabrication Techniques for Manufacturing Electronics Parts

a man laser cutting a sheet metal

Sheet metal fabrication various techniques essential for manufacturing electronic components with precision and efficiency. These techniques involve shaping and manipulating sheet metal to create parts that meet the specific requirements of electronic devices.

Check the various fabrication techniques commonly employed in the electronics industry below:

- Laser Cutting

Laser cutting is a highly precise fabrication technique used to cut intricate shapes and patterns from sheet metal. In this fabrication method, a high-powered laser beam gets directed onto the metal surface, melting or vaporizing the material along the desired cutting path.

Laser cutting remains highly valued because it allows for the manufacture of components with complex geometries, while ensuring negligible material waste. It is commonly used to fabricate precise enclosures, mounting brackets, and heat sinks for electronic devices.

- Stamping

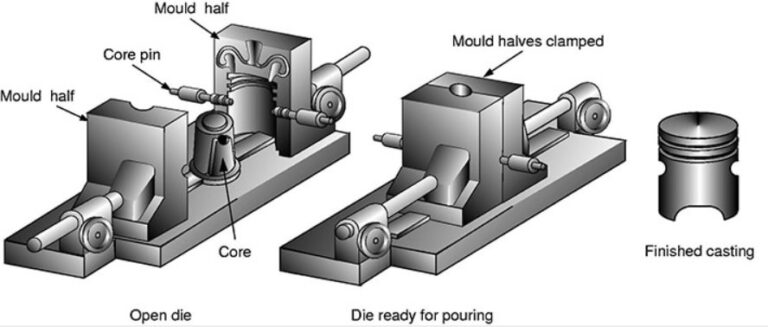

Stamping involves the use of a press machine to deform sheet metal into specific shapes using a die and punch set. In this technique, the manufacturer places a metal sheet between the die and punch, and pressure is applied to form the desired shape. As such, stamping is ideal for producing large quantities of identical parts quickly and cost-effectively. In the electronics industry, stamped components such as connectors, mounting brackets, and housing panels are commonly used in various devices.

- Punching

Punching is a fabrication technique that involves creating holes or features in sheet metal using a punch and die set. For this method, the punch gets forced through the metal sheet, shearing out the desired shape. Similarly, punching remains efficient for producing holes, slots, and other features with high accuracy and repeatability. In electronics manufacturing, punched components such as ventilation holes, cable management slots, and mounting points are essential for device functionality and assembly.

- Bending

Bending is the process of deforming sheet metal along a straight axis to form angles, curves, or complex shapes. Manufacturers carry out this technique using a press brake or bending machine, which applies force to the metal sheet to bend it to the desired angle. Bending is commonly used to fabricate structural components, metal chassis, and enclosures for electronic devices, providing strength and rigidity to the final product.

- Welding

Welding is the process of joining two or more pieces of metal together using heat and pressure to create a strong, permanent bond. In electronics manufacturing, welding is usually employed to assemble sheet metal components, join structural elements, and create sealed enclosures for delicate electronics. Common welding techniques include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and spot welding. Note that each of these welding methods offers unique advantages for specific applications.

- Riveting

Riveting is a mechanical fastening technique used to join two or more pieces of sheet metal together using rivets. In essence, a rivet gets inserted into pre-drilled holes in the metal sheets, and the tail end becomes deformed to create a secure joint. Riveting is suitable for applications where welding is not feasible or desired. This includes applications that involve assembling lightweight components or joining dissimilar materials. In electronics manufacturing, riveting is commonly used to assemble sheet metal enclosures, mounting brackets, and structural supports.

Conclusion

Sheet metal fabrication plays a pivotal role in the electronics industry, offering various benefits and applications. From customization to precision and efficiency, these benefits help improve the landscape of electronic innovation.

Overall, the diverse fabrication techniques, from laser cutting and stamping to bending and welding, highlight the importance of sheet metal fabrication in electronic manufacturing. By understanding the unique advantages and applications of sheet metal fabrication, manufacturers can optimize production processes, enhance product quality, and meet the evolving demands of the electronics market.