How Do Flow Wrappers Improve Packaging Efficiency

In today’s rapidly evolving manufacturing industry, improving packaging efficiency has become critical. With the increasing production demand, manufacturers are constantly seeking innovative packaging solutions to adapt to the fast-paced market and achieve a competitive advantage in packaging efficiency.

Among many packaging technologies, flow wrappers stand out and become the key technology to improve packaging efficiency. Its unique horizontal form-fill-seal mechanism makes the entire packaging process more continuous and efficient.

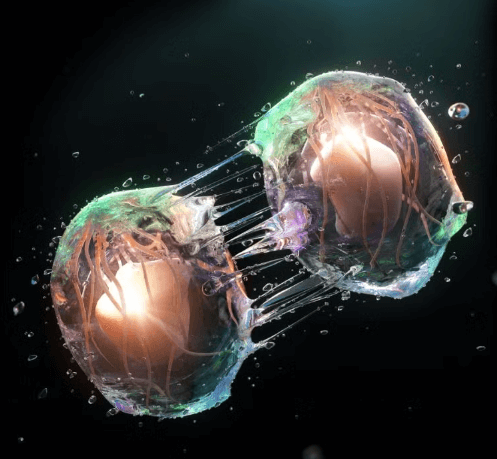

Core Principle of Flow Wrappers

The unique feature of flow wrappers is their horizontal form-fill-seal mechanism. This design gives them a superior packaging advantage.

The horizontal form mechanism makes the entire packaging process in the horizontal direction, compared to the traditional vertical packaging, which makes the operation more continuous, thus improving the packaging efficiency.

The characteristics of horizontal operation also make the flow packaging machine show strong adaptability and flexibility. Unlike fixed vertical structures, horizontal form mechanisms are easier to adapt to products of different sizes and shapes. This means that a single flow wrapper can handle many different products without tedious adjustments and tool changes.

This adaptability allows the production line to respond more flexibly to the packaging needs of different products, ensuring the efficient operation of the manufacturing process. The improved adaptability also brings a wider range of applicability, enabling the flow packaging machine to perform well in the face of a diverse range of products.

Speed and Accuracy

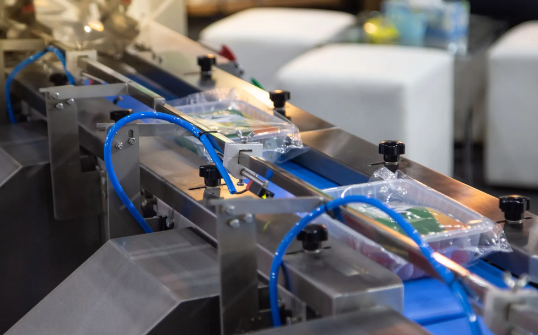

Ruipuhua’s flow wrappers have achieved significant breakthroughs in speed and precision, becoming an efficient enabler on the packaging line.

On one hand, the horizontal form-fill-seal mechanism allows the packaging line to achieve high-speed continuous operation. This not only greatly improves the production capacity of the packaging line, but also reduces downtime and ensures the continuity of the production process.

The high-speed operation of the flow packaging machine makes it possible to complete the packaging of large quantities of products in a short time, which adapts to the needs of modern manufacturing industry for efficient production.

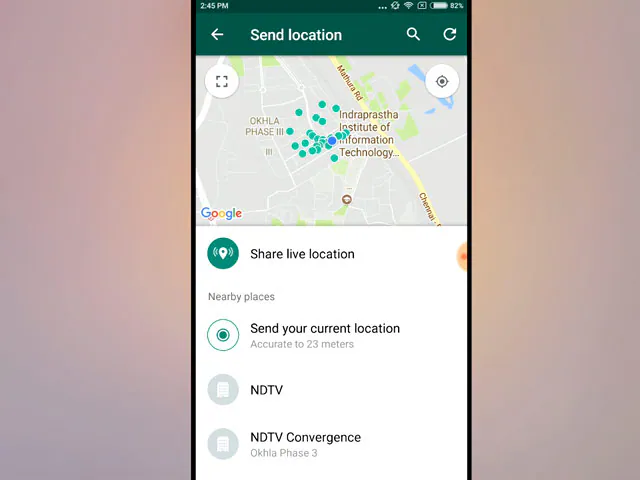

On the other hand, the flow packaging machine ensures the continuity of the packaging line to the greatest extent through its efficient principle of reducing downtime. The application of sensor technology enables the flow packaging machine to monitor the parameters in real time and find and solve potential problems in time.

This predictive maintenance feature greatly reduces the risk of machine failure, ensures stable operation of the packaging line, and further improves packaging efficiency.

In addition, through its precise operation, the flow packaging machine reduces the error rate and ensures the high quality of the product. Each step is carefully designed and tightly controlled, ensuring that every product goes through the same high standard packaging process.

This precision is particularly critical for manufacturing, not only improving packaging efficiency, but also ensuring product consistency and quality.

Conclusion

In summary, flow wrappers through their core principles, speed and precision, and other advantages, have become an important driving force for improving packaging efficiency in modern manufacturing.

The flexibility and adaptability of the flow packaging machine enable it to play an important role in different industries and different products to meet diverse packaging needs.

With the continuous innovation of technology, the flow packaging machine is expected to further improve its performance and adapt to the needs of more industries. In the future, it will continue to play a key role in the field of packaging technology and make greater contributions to the efficient production of the manufacturing industry.