HDPE Filament: A Complete Guide

High-Density Polyethylene (HDPE) is a type of thermoplastic polymer made from petroleum.

It is known for its strength, durability, and resistance to chemicals, making it an ideal material for a wide range of applications, including 3D printing. Before we have a look at HDPE filament, its important to have a look at the best 3D printing software. Many are available but we recommend using SelfCAD. SelfCAD is an easy to use

Contents

- Characteristics of HDPE Filament

- 3D Printing with HDPE Filament

- Post-Processing and Finishing

- Applications of HDPE Filament

- Tips for Successful 3D Printing with HDPE Filament

- Advantages of HDPE Filament

- Comparing HDPE to Other 3D Printing Materials

- Safety Considerations

- Storage and Handling

- Troubleshooting Common Issues

- Environmental Impact

- Compatibility and Modifications

- Successful 3D Printing Projects with HDPE Filament

Characteristics of HDPE Filament

HDPE filament offers the following key characteristics:

- High strength and durability.

- Resistance to impact, chemicals, and moisture.

- Excellent layer adhesion.

- Lightweight.

- Good flexibility.

- Low friction coefficient.

- Recyclable.

3D Printing with HDPE Filament

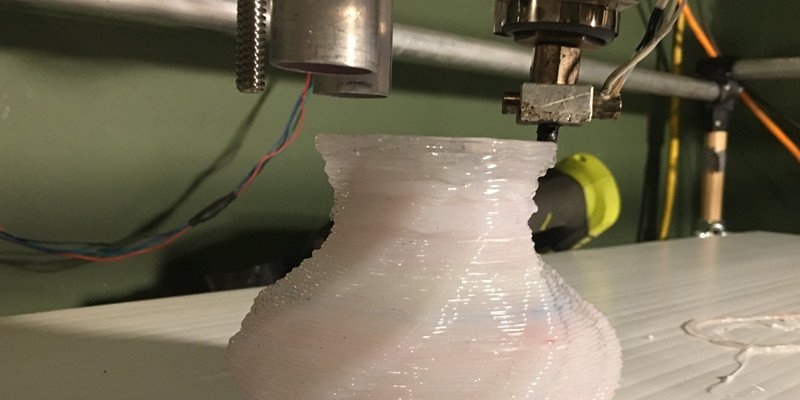

HDPE Filament for 3D printing. Image source: Felfil

- Printing Temperature

HDPE filament typically prints well at temperatures ranging from 200°C to 240°C. The exact temperature depends on your 3D printer and the specific brand of filament you are using. It’s essential to check the manufacturer’s recommendations for temperature settings.

- Bed Adhesion

HDPE has a tendency to warp, so using a heated bed at temperatures around 60°C can help with bed adhesion. Some users also apply a thin layer of adhesive, such as hairspray or a specialized bed adhesion solution, to improve adhesion.

- Cooling

HDPE generally benefits from minimal cooling. Turning off or reducing the cooling fan speed can help prevent warping and ensure better layer adhesion.

- Print Speed

Moderate print speeds are recommended for HDPE filament. Printing too quickly can result in poor layer bonding and surface quality. Start with a speed of around 30-60 mm/s and adjust as needed.

- Retraction Settings

Fine-tuning retraction settings can help reduce stringing and oozing. Experiment with retraction distance and speed until you achieve the desired results.

Post-Processing and Finishing

- Sanding and Smoothing

HDPE can be sanded to smooth out rough surfaces. You can start with lower-grit sandpaper and gradually move to higher grits to achieve a polished finish.

- Painting and Coating

HDPE can be painted or coated for aesthetics or added protection. Ensure that the surface is clean and free of any contaminants before applying paint or coatings.

Applications of HDPE Filament

3D printing with HDPE filaments. Image source: 3DSourced

- Prototyping

HDPE is widely used in rapid prototyping due to its durability and ease of printing. It’s suitable for creating functional prototypes and testing designs.

- Functional Parts

HDPE’s robustness and resistance to chemicals make it suitable for producing functional parts like gears, containers, and mechanical components.

- Outdoor and Water-Resistant Projects

Due to its resistance to moisture and UV rays, HDPE is ideal for outdoor and water-resistant projects such as garden equipment, kayaks, and outdoor furniture.

Tips for Successful 3D Printing with HDPE Filament

- Calibrate your 3D printer for optimal settings.

- Use a heated bed and adhesion aids to prevent warping.

- Experiment with print temperatures to find the best setting for your specific filament.

- Pay attention to retraction settings to minimize stringing.

- Consider minimal or no cooling during the printing process.

- Practice good post-processing techniques for a polished finish.

Advantages of HDPE Filament

HDPE filament offers several advantages that make it a popular choice in the world of 3D printing:

- Durability: HDPE is known for its strength and impact resistance, making it an excellent option for producing functional and long-lasting parts.

- Chemical Resistance: It is highly resistant to a wide range of chemicals, making it suitable for applications in corrosive environments.

- Moisture Resistance: HDPE is impervious to moisture and doesn’t absorb water, which is particularly advantageous for outdoor or water-related projects.

- Recyclability: As a recyclable material, HDPE supports environmentally friendly practices by reducing waste.

- Low Friction Coefficient: HDPE has a low friction coefficient, making it suitable for parts that require smooth and low-wear surfaces, such as bearings and sliding components.

- Versatility: HDPE’s versatility allows for a variety of applications, from rapid prototyping to creating custom mechanical components.

Comparing HDPE to Other 3D Printing Materials

HDPE, a 3D printing material. Image source: 3DSourced

While HDPE has its advantages, it’s essential to understand how it compares to other 3D printing materials. Here’s a brief comparison with a few common materials:

- PLA (Polylactic Acid): PLA is biodegradable, easy to print with, and has less warping than HDPE but lacks the same level of durability and chemical resistance.

- ABS (Acrylonitrile Butadiene Styrene): ABS is stronger than PLA but more challenging to print with due to higher warping tendencies and fumes. HDPE is easier to print and has better chemical resistance than ABS.

- PETG (Polyethylene Terephthalate Glycol): PETG is a good compromise between PLA and ABS, offering strength, flexibility, and ease of printing. HDPE has better chemical resistance but might be less flexible.

Safety Considerations

When 3D printing with HDPE filament, consider the following safety precautions:

- Ensure proper ventilation in your printing area, as some emissions from melting HDPE can be harmful if inhaled.

- Use personal protective equipment like gloves and safety glasses when handling HDPE filament and finished prints.

- Follow manufacturer guidelines for handling and disposing of HDPE waste.

Remember that successful 3D printing with HDPE filament often requires experimentation and fine-tuning, so don’t be discouraged by initial challenges.

With practice and careful attention to settings, you can harness the benefits of HDPE for a wide range of projects.

Storage and Handling

Proper storage and handling of HDPE filament are essential to maintain its quality and performance. Here are some tips:

- Storage: Store your HDPE filament in a cool, dry place away from direct sunlight, moisture, and dust. Consider using a sealed container or vacuum-sealed bags to prevent exposure to air, which can lead to moisture absorption.

- Moisture Control: HDPE is sensitive to moisture, which can negatively affect print quality. If your filament absorbs moisture, you may notice popping or hissing sounds during printing. To address this, you can use a dehumidifier or a filament dryer to remove moisture from the spool before printing.

- Clean Nozzles: Regularly check and clean your 3D printer’s nozzle. The accumulation of residue can lead to clogs and affect print quality.

Troubleshooting Common Issues

When working with HDPE filament, you may encounter some common issues:

- Warping: If you experience warping, try increasing the bed temperature and ensuring proper bed adhesion. Consider using a brim or raft to help keep the print anchored to the bed.

- Stringing: Stringing or oozing can be mitigated by adjusting retraction settings. You can also experiment with lower print temperatures to reduce this issue.

- Layer Adhesion: Achieving good layer adhesion is crucial for strong prints. Make sure your printer is calibrated, and the nozzle is at the correct height from the bed. Printing at a slower speed can also improve layer bonding.

- Bridging: HDPE is not the best material for bridging large gaps due to its flexibility. You may need to use support structures for complex overhangs.

Environmental Impact

HDPE is a recyclable material. Be conscious of its environmental impact and consider recycling your failed prints or unused scraps.

You can often find local recycling facilities that accept HDPE. Reducing waste and reusing filament spools can also contribute to sustainability.

Compatibility and Modifications

Check your 3D printer’s compatibility with HDPE filament. Some printers may require specific modifications or upgrades to handle this material effectively.

This can include upgrading the hotend or adding an enclosure to maintain a stable printing environment.

Having looked at the all the details about HDPE filament, it’s also important to have a look at the best 3D printing software. There are many that you can use but we recommend using SelfCAD. SelfCAD is one of the easiest 3D modeling software available that runs both online as well as on Windows and Mac. It comes with all the necessary tools for necessary for creating 3D models and even preparing them for 3D printing without having to switch to a separate sofyware. You can also use the software to fix issues with the meshes in your designs. For example, you can use it to fix non manifold errors in your files, as shown in the video below.

You can also import STL files and modify them based on your requirements. For example, you can import and color the STL file, as shown in the video below.

After creating your 3D models, you can then use the online slicer of SelfCAD to prepare your designs for 3D printing by generating the Gcode to send to your 3D printer. Get to know how to slice files using SelfCAD slicer in the video below.

Successful 3D Printing Projects with HDPE Filament

HDPE filament is a versatile material that is ideal for a wide range of 3D printing applications. Its durability and resistance to chemicals make it a valuable choice for functional parts and outdoor projects.

By understanding its characteristics, proper handling, and fine-tuning your 3D printer settings, you can achieve excellent results with HDPE filament.

As technology and materials continue to advance, always stay updated on the latest developments in 3D printing to make the most of HDPE and other materials for your projects. Happy 3D printing!

Also Read: Things to Do When Troubleshooting a Copier: Expert Repair and Maintenance Tips